Remember growing up and playing with tinker toys, Legos, and other construction themed toys? These toys came in a variety of shapes, sizes and colors and let your creative side go wild looking for new ways to assemble them into a functional shape. Sometimes you would try and build everyday items using the different styles of pieces and other times you could create a totally new invention like a combination back scratcher and windmill that used a variety of different shaped pieces all assembled together. These toys allowed us to be creative and come up with ingenious designs using the different tools and pieces that came with the kits. Now, fast forward to adulthood, and imagine being paid to come up with new inventions every day using a variety of different materials and tools. This is the job of a Machining Engineer and every day they get to try different designs and tools to accomplish a job that is needed by manufacturing engineering. With each component, subassembly and automobile design there are assembly challenges that need customized tooling, gears, axles and even finished components to complete the manufacturing process.

Day in the life of a machining engineer

A day on the job as a machining engineer is never the same from day to day. There are planned projects where the design and assembly team will discuss development on a new design and the assembly process that will be needed to build the new vehicle. These projects allow the machining engineer to work with the design team from the beginning of the design and provide insight into what will be possible with the restrictions of the materials, tools and equipment they have to work with. By working with the design team early on this helps to ensure that they will not be faced with an insurmountable challenge when it comes to designing a new part.

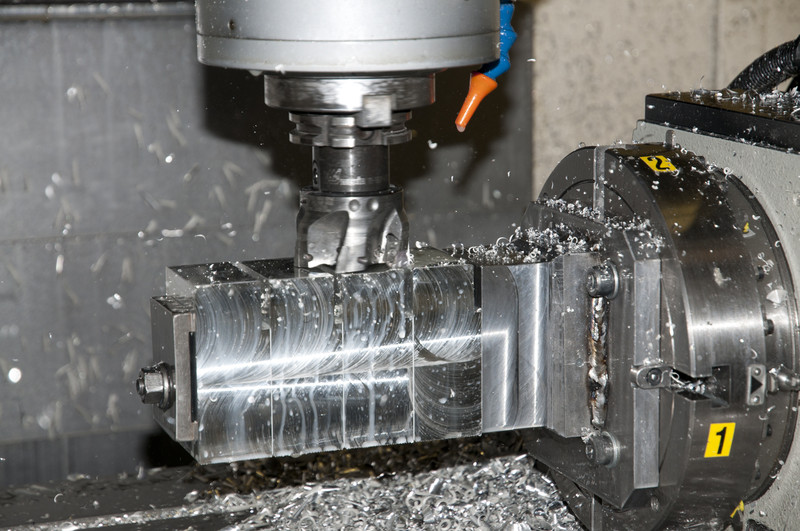

The truly creative part of the machining engineer role comes up when a new and anticipated challenge comes up from the design or manufacturing processes. When these challenges come up then the machining engineer gets to be truly creative in finding a solution. They may go through multiple iterations of a design change different parameters and fine tuning the end product so that it will function as needed. They will build prototypes and test each one before finalizing their solution and moving forward with assembly and production. Machining engineers must always use their creative minds to come up with new ways to use existing tools and materials when faced with these challenges.

Education and experience required for a machining engineer

The base requirements for working in the automotive industry as an engineer are going to be a degree in engineering or a closely related field such as materials science or even physics. These technical degrees will give the machining engineer a solid understanding of material properties, statics, dynamics and thermodynamics when designing components and tooling for use in the automotive industry.

In order to earn the technical degree required colleges and universities are going to look for a solid foundation in several areas while a potential student is in secondary school. These areas include science, physics, chemistry and math as well as calculus, if this course was available in your school. Additionally, colleges are going to look for students who are active in extracurricular activities such as athletics, marching band or National Honor Society. Students who were well-rounded and engaged students during high school are able to better balance their time and have a higher success rate in completing a college program.

If you are looking for a career that will allow you to flex your creative muscles on a day to day basis (and you still have boxes of Legos in your closet) then a career as a machining engineer might be the right path for you to consider.

Comments 2

There are a lot of engineering and machining engineers that are needed now. I know a lot of companies are trying to make more machines and efficient products to help move everything along in the business world. I used to do engineering in school.

Like you said, a machine engineering is something that has gotten bigger over the years and will continue to get bigger because of how fast the processes are. I think that someone that is making a prototype for an invention should hire an engineer to make sure that the product is made and modified as quickly as possible. The faster that an idea is made real, the faster that someone can profit off of their inventions.