Automotive Design Engineers are the people in the automotive world who turn ideas into functioning designs. There are many different types of design engineers in the automotive field, but most of them require a similar skill set. I have been a design engineer in the automotive world for six years now and it has been an incredible rewarding career. Over the time I have worked in this field, I learned a few specific things that really helped me advance my career and were essential to get me where I am today. Part one of this article talks about the three most important technical skills you should really focus on if you want to be a great automotive design engineer. Later in Part 2, I’ll discuss the three most important non-technical traits you should focus on.

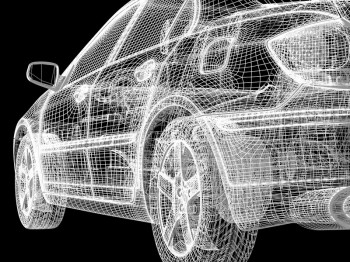

1. CAD Experience

If you are a design engineer you will be working with CAD (Computer Aided Design) sometimes once a day and sometimes every minute. It is your main tool for determining quickly how your parts function and fit together. You should really know how to create, move and analyze a 3D model.Showing that you know at least one CAD program is absolutely necessary to get any job as a design engineer.

How much drafting ability you actually need depends on the size of your company and what specifically you are making. At the smaller company where I was designing bearings, I used CAD almost every day and took a part from a general calculation or idea all the way to a finished design print for a customer. When I worked for an OEM, and now that I am in a larger company, I used CAD only for analysis and calculations. OEMs and larger companies usually have a separate department that is entirely dedicated to making models and drawings. As a design engineer at these types of companies, you are responsible for making the part function and making sure that the calculations and tolerances are correct. However all changes are controlled by a separate department (or outsourced).

How much drafting ability you actually need depends on the size of your company and what specifically you are making. At the smaller company where I was designing bearings, I used CAD almost every day and took a part from a general calculation or idea all the way to a finished design print for a customer. When I worked for an OEM, and now that I am in a larger company, I used CAD only for analysis and calculations. OEMs and larger companies usually have a separate department that is entirely dedicated to making models and drawings. As a design engineer at these types of companies, you are responsible for making the part function and making sure that the calculations and tolerances are correct. However all changes are controlled by a separate department (or outsourced).

Whether you make the drawings on your own or you need to interact and analyze them, you will need in-depth knowledge of how your CAD system works. This can be tricky because it seems like every company uses their own CAD brand for their systems. I have worked at 4 different automotive companies and have used 5 different brands of modeling software! The good news is that these different software products are all very similar in their own concepts. The tricky part comes with where all the buttons are located, how to open your screen, and how to take a cross section or make a sketch onto your part. (This can be really frustrating when switching systems!)

My advice would be to start with the base model of 3D modeling: Solidworks. Solidworks is the go-to program when you are first learning how to think as a 3D designer. It is user-friendly and intuitive – in fact most designers will tell you that they wish the more advanced programs (CATIA/Pro-E/Unigraphics) were as simple and user-friendly as Solidworks. For learning 3D CAD I recommend using the training company Solidwize (affiliate) if you are just starting out. All of their programs are online based, and they will focus on the concepts that you will use 90% of the time wherever you go to work.

2. GD&T Expertise

The first thing you should know as an Automotive Design Engineer is GD&T. When referring to GD&T, I mean everything from engineering drawing symbols, to tolerance stack ups. You cannot design an automotive part without understanding the core concepts of dimensioning first. It is critical that you get some hands-on experience with existing drawings, and understand how a drawing is controlled. When you move from individual parts to assemblies, any poorly dimensioned or uncontrolled features will stick out like a monkey at a funeral. Knowing features and controls of parts is of paramount importance to design engineering. Before you can get into complex stress calculations, or load properties of different materials, you need to know how to read a basic engineering drawing.

The first thing you should know as an Automotive Design Engineer is GD&T. When referring to GD&T, I mean everything from engineering drawing symbols, to tolerance stack ups. You cannot design an automotive part without understanding the core concepts of dimensioning first. It is critical that you get some hands-on experience with existing drawings, and understand how a drawing is controlled. When you move from individual parts to assemblies, any poorly dimensioned or uncontrolled features will stick out like a monkey at a funeral. Knowing features and controls of parts is of paramount importance to design engineering. Before you can get into complex stress calculations, or load properties of different materials, you need to know how to read a basic engineering drawing.

For a great course on GD&T, check out GDandTBasics.com. This site is by far the best resource to cover all the training that an engineer will need for GD&T and explains in detail every geometric symbol that you need to know in automotive engineering.

You need to know:

- Basic dimensioning principals. This means you should understand how to use basic math and trigonometry to determine the length of any feature on the part – especially the ones that are not directly dimensioned.

- How tolerances stack up with each other, and be able to add them together to determine worst cases.

- How to read a feature control frame.

- The envelope principal and the limitations of geometric control.

- Geometric drawing symbols and how they are controlled and measured.

- Chamfers and fillets how they are used.

- How datums are used in a drawing and how specific features relate to them.

- Surface roughness properties.

- Title blocks and what information is contained within them (can vary by company).

These concepts are just the start of what you should know for automotive engineering. At each company and within each design role you will have to know even more in depth topics. The good thing about these advanced design concepts is that you will usually be trained on them specifically for your role once you start your job. However, each and every company will expect you to be an expert of core design concepts, so make sure you learn your basic GD&T. You won’t last long without this knowledge.

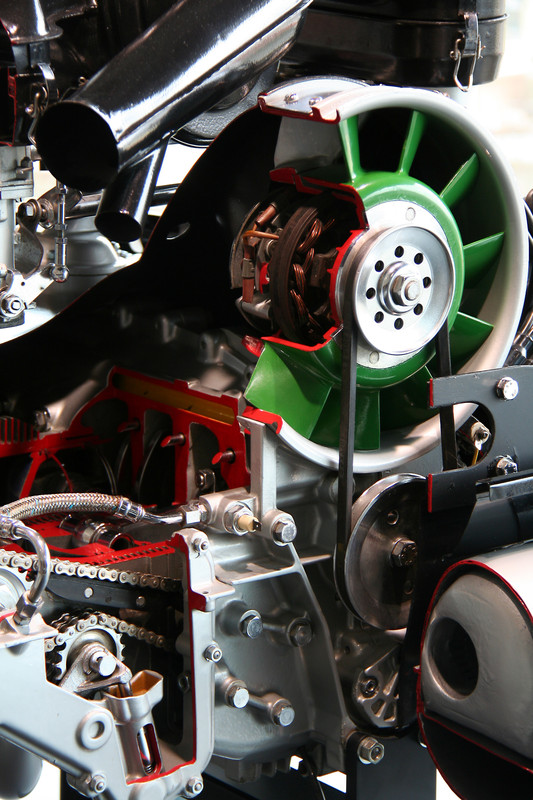

3. Design for Manufacturability (DFM) methods

As someone who has worked both in the early stages and the later production stages of design, I can tell you that the more you know about the manufacturing process the better. It is a fact in economics as well as in automotive production: The later that a change is made; the more expensive/difficult the change is to make. This is why the manufacturability of a product should be determined well before the part ever hits the floor.

As the automotive industry advances, the role of the design engineer ties more and more into the production realm. In the past, application or design engineers created the functional design of the product and then it was handed over to the manufacturing plant to create the product. Now the Application Department is expected to support the production throughout the life of the vehicle production in a nearly full capacity. This means that any overlooked problems with the manufacturability of the parts will always be the design engineer’s responsibility. Deviation requests from the production department will come up time and time again when a material is difficult to fabricate, or two parts will not assemble. These can range from minor annoyances to complete redesign of a part (and potential millions in costs). This is why the later design stages and handover to production is so critical. As a designer you should be deeply involved when the parts are beginning their prototype production. Sometimes you may only have a limited scope of what can go wrong with the part. However when assembly trials start, the real problems begin to come out.

As the automotive industry advances, the role of the design engineer ties more and more into the production realm. In the past, application or design engineers created the functional design of the product and then it was handed over to the manufacturing plant to create the product. Now the Application Department is expected to support the production throughout the life of the vehicle production in a nearly full capacity. This means that any overlooked problems with the manufacturability of the parts will always be the design engineer’s responsibility. Deviation requests from the production department will come up time and time again when a material is difficult to fabricate, or two parts will not assemble. These can range from minor annoyances to complete redesign of a part (and potential millions in costs). This is why the later design stages and handover to production is so critical. As a designer you should be deeply involved when the parts are beginning their prototype production. Sometimes you may only have a limited scope of what can go wrong with the part. However when assembly trials start, the real problems begin to come out.

Manufacturability comes from experience but usually breaks down into common sense. Remember the KISS method – Keep It Simple, Stupid. If you are a design engineer your goal should be to put out the simplest, cheapest product that meets the functioning requirements, nothing more. Keeping things simple is much harder for your typical engineer who wants each and every design to be perfect. There is an old saying, that goes “A great engineer can do for a dollar, what a good engineer can do for two.” That door dampener you are designing might benefit from adding a shock absorber, but if all it needs to do is help with basic door movement, you should leave it out. Knowing the impact of each feature, part and tolerance you designate on a part will make you a great design engineer. Your first goal is always function, but your second goal should always be simplicity.

The best way to keep a focus on design for manufacturability is to make sure the production engineers are kept in the loop near the middle, and later design stages.

Check out part 2 of our Essential Qualities of Automotive Design Engineers for information on the non-technical skills you should aquire!

Comments 7

i love this very thank you very much. i never knew it was possible….

GOD bless you please email me back @remidaves@gmail.com

thanks

thank you for your inspiral word……. now my knowledge is litlle wide than my companians…. thank you

i love this, this my dream my life my everything and is gonna come true

Great will choose as my career

Inspiring

We are always looking for great engineers http://www.rcoeng.com/

We are always looking for highly skilled automotive engineers!

http://www.rcoeng.com/