Have you ever put two things together and suddenly created a new and useful tool? Do you constantly look for new ways to improve the tools and objects you use in day-to-day life and find simple and creative ways to do a job differently or more efficiently? Do you have a garage full of inventions all in various stages of development? If any of these questions sound familiar then a job in Automotive Design Engineering might be the right position for you. Automotive Design Engineers take a design concept and help to bring it to production by drawing and defining all the critical parameters needed to build a product. Their main goal is that all components will work within the automobile and to design newer or more efficient components to launch to the market.

Life as a design engineer in the automotive world

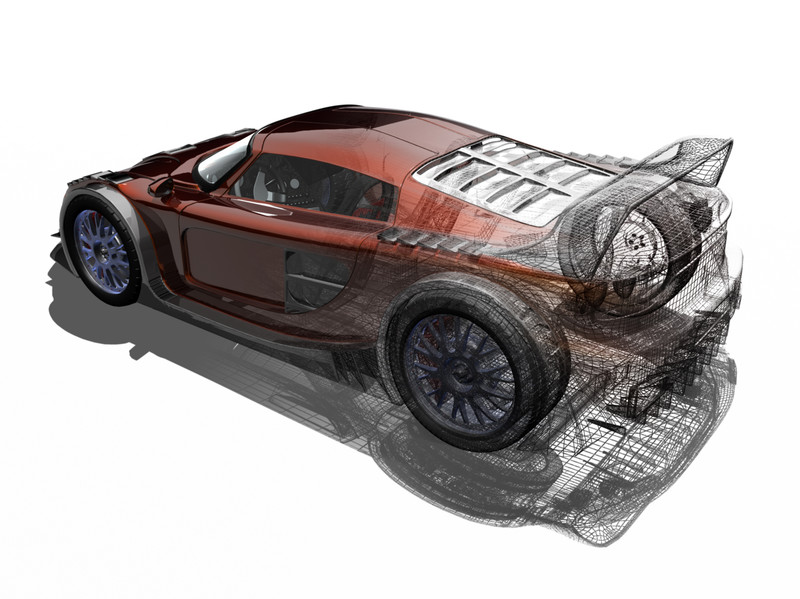

Design engineers work in all phases of the product development life cycle but are most prominent in the concept and design phases. During the concept phases of a product design, design engineers will work with prototypes and conceptual artwork to begin and build a working model of the vehicle or component. As a part of this design phase design engineers will also conduct benchmarking activities and look at competitive products and conduct teardowns in order to reverse engineer their solutions and better understand them and see if there is technology that can be leveraged in their own design. Once the concept of the design is finalized it is time to enter the true design phase of the development process.

Concept development

During the definition phase of the development life cycle the design engineers will begin to solidify the product requirements and the critical parameters that will define how it operates. Design engineers will work with the both customers and suppliers to ensure that their design integrates with no issues into the vehicle and works harmoniously with the other components within the design. With inputs from the customer they will outline a design envelope that the end design must fit within and then input these critical parameters into the drawings. They will work with customers to define the appropriate certifications the design must meet such as USCAR or FMVSS that have a long list of testing and performance parameters the end product must meet in order to be sold in different product markets. These requirements will then be highlighted on the drawing and the next phase of the development process will commence.

Solidify the design

Once the design engineer has fully conceptualized the end product then it’s time to begin the design drawings. Using the parameters outline in the concept phase the design engineer will begin drawing the part and assigning the correct dimensions and tolerances. The design engineer will select the materials that will be used to build the part and that meet the operating requirements and the operating environment. The design engineer must also be aware of proper Geometric Dimensioning and Tolerancing to ensure that the manufacturing meets the true design intent of the part. As the design begins to solidify, they will conduct design reviews and ask quality, test, manufacturing and other design engineers to review the drawings, ask questions and highlight any concerns they may have with the design. It is important for design engineers to incorporate these inputs early in the design when it is easier to make changes and modifications in the designs. Once the design reaches a certain point then a change control process is initiated requiring a more formal approval process for any changes. The design engineer will construct prototypes and begin conducting design validation testing during this phase and will focus the testing on the most stringent requirements that will possibly cause issues during validation testing.

Product validation and production

After the design engineer has a working prototype model and successfully passed design validation testing then they will enter the product validation and production phase. The design engineer will work with the manufacturing engineers and build parts on production intent processes and equipment so that the part will be representative of the end product process. These parts will then enter production validation testing where they will be tested to all the key criteria outlined in the product design including performance and NVH. In parallel the design engineer will work with the manufacturing engineer to validate and mistake proof the manufacturing line to hopefully prevent future manufacturing issues.

Education requirements for design engineers

The basic requirements for a design engineering job are a Bachelor’s Degree in an appropriate engineering field such as a degree in mechanical engineering, mechanical systems, or subassembly design work. A Master’s degree is not required but will help in getting a position in a highly specialized field or help you to win over the competition for this highly competitive position.

Want to know what it takes to be an automotive design engineer? Go check out The 6 Essential Qualities of a Design Engineer.