When you hear the words metallurgical or materials you tend to think of someone digging in a mine or prospecting in the mountains of California. (Yes, they still have mines and claims can be filed even today.) But these two terms encompass a whole area of expertise within the automotive engineering arena and are an integral part of every aspect of the automotive design process. Each time you interact with an automobile there are multiple levels where a metallurgical or materials quality engineer were involved in the design, development and validation of these processes.

Example of a metallurgical quality engineering project

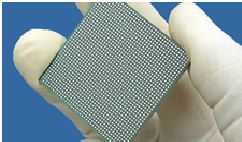

Throughout my career as an electrical engineer, I have had the opportunity to work on a variety of projects but one that was of particular interest involved a metallurgical quality issue on a semiconducto r product. This particular project revolved around a quality issue with a processor when it was attached to a printed circuit board or PCB. The PCB or motherboard, in this case, is the part of an electronic assembly that provides the interface between all the components on the motherboard. These components include the processor, graphics chip, LAN and all the associated components that support the functionality and interface with these components. Additionally, the PCB contains all the traces that facilitate communication between the different components so that they will function correctly. I’ve included a picture of a PCB for reference for better understanding. Now, the project that I’m referring to was rather specific and involved a ball grid array (BGA) component mounted on a PCB that would face very rough operating conditions when it was in the field. BGA components describes the way that a component is attached to the circuit board and, in this case small balls of solder are attached to the bottoms side of the processor which will then melt to attached to the corresponding grid on the PCB.

r product. This particular project revolved around a quality issue with a processor when it was attached to a printed circuit board or PCB. The PCB or motherboard, in this case, is the part of an electronic assembly that provides the interface between all the components on the motherboard. These components include the processor, graphics chip, LAN and all the associated components that support the functionality and interface with these components. Additionally, the PCB contains all the traces that facilitate communication between the different components so that they will function correctly. I’ve included a picture of a PCB for reference for better understanding. Now, the project that I’m referring to was rather specific and involved a ball grid array (BGA) component mounted on a PCB that would face very rough operating conditions when it was in the field. BGA components describes the way that a component is attached to the circuit board and, in this case small balls of solder are attached to the bottoms side of the processor which will then melt to attached to the corresponding grid on the PCB.

This is the background, now for the problem that we were faced with solving with our team of metallurgical and materials analyst quality engineers.

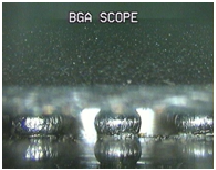

When the PCB with the attached processor was in the field it would face rough handling, vibration, and flexion. These detrimentalforces would put pressure on the solder joints of the processor and cause them to flex and

PCB with the attached processor was in the field it would face rough handling, vibration, and flexion. These detrimentalforces would put pressure on the solder joints of the processor and cause them to flex and  crack until they ultimately would break, severing the connection to the PCB and causing the part to fail. Our team was called in to complete a root cause analysis of this issue and identify a solution.

crack until they ultimately would break, severing the connection to the PCB and causing the part to fail. Our team was called in to complete a root cause analysis of this issue and identify a solution.

We analyzed how the parts performed in both a shock event and a long term vibration exposure and what we found was that the corner solder balls of the part were subject to greater forces due to the combined flexure of the component and the motherboard. We then implemented two solutions, first, we changed the solder material to something that is more flexible and able to absorb the shock that the solder joint would see in the field and second, we switched the purpose of the solder balls in the corner most locations and made them non-functioning or inactive connections so that if a break occurred where there were the most stressed then the part would still function correctly.

This project resulted in us implementing a new design guideline within our PCB design team to allow for the increased mechanical stresses products would see in the field. If this type of work sounds interesting to you then maybe consider a career in this engineering field.

Becoming a Metallurgical and Materials Analyst Quality Engineer

The first steps towards a career in this field are obtaining a degree in a related field. Engineering degrees are always a sound foundation but when you move into this specialty arena you may want to consider a degree in Materials Science. This degree will provide the detailed background you need to understand the metallurgical structure of the parts and designs you will be working within the field. To earn this degree and enter a university, you will need a strong background in math, science, physics and chemistry so that you will be prepared when you enter college.

The Metallurgical and Materials Analyst Quality engineer role has become increasingly important in the industry in particular because technology is shrinking and becoming more precise. There is considerable opportunity in this field for those who are interested.