Note: This is an ongoing series that we are adding to each week. Be sure to check back in to see the completed list of automotive engineering careers!

Have you ever truly looked at an automobile and seen the true complexity of each component that it takes to put together a vehicle? From the sleek, aerodynamic design of the vehicle body to the silicon within the circuitry that control the vehicle and the plethora of parts in between you will find an example of every engineering discipline all in place. The automotive industry offers a tremendous range of opportunities for the engineers of tomorrow. No matter what area of engineering you choose to pursue you’ll find an application for your specialty within the wide range of automotive engineering career choices:

Click the links for in-depth information on each automotive engineering job.

- General Automotive Engineer – Automotive engineers work within a variety of different specialties in the automotive industry that are specific to automobiles. There are three varieties of automotive engineers design, quality and production that manage the development and manufacturing of automobiles.

- Manufacturing Engineer– Manufacturing engineers are responsible for developing the manufacturing processes for the vehicle and coordinating the optimization of the process so that it is done efficiently and without mistakes.

- Test Engineer– Test engineers partner with design and quality engineers in the prototype and validation phases of development. Test engineers will conduct environmental, stress and performance testing to determine if the components or fully assembled vehicle meet the design requirements.

- Design Engineer– Design engineers work in the concept and design phases of automotive design and are responsible for the actual design and conceptualization of the vehicle itself. Design engineers work with CAD designers to put the bill of materials and drawings together that are the blueprints for building an automobile.

- Process Planner– Process planners coordinate the intake of orders from customers and then schedule the production line to build vehicles to fulfill customer orders. They manage all aspects of production planning from the intake of components to shipping the final product to the customer.

- Materials Development Engineer– Working as a materials development engineer allows you to develop and select new materials to meet the increasingly stringent design and performance requirements of future automobiles.

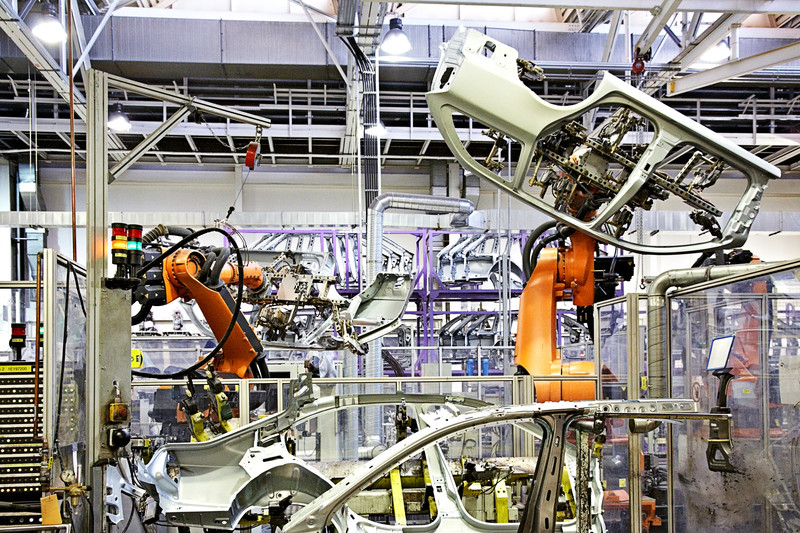

- Robotics Engineer– Robotics are very prevalent in the manufacturing production lines for automobiles. Robotics Engineers are responsible for the design, maintenance and programming of the robotics involved in the production line.

- Tooling Engineer– Assembling a vehicle involves specialty equipment to ensure proper fit, measurements and placement of components during assembly. Tooling Engineers are responsible for designing, building, calibrating and implementing the tooling used during assembly.

- Change Management Engineer– Designing vehicles and the components that go into them will require multiple iterations to get everything to fit and function together correctly. Change Management Engineers manage these changes and ensure that when one part is modified it does not negatively impact another part within the vehicle.

- Supplier Quality Engineer– Supplier Quality Engineers manage the external suppliers that provide materials and components that are used in the assembly process and ensure that incoming materials and components meet design specifications and quality levels and work with suppliers to fix any issues if a defective or non-conforming part is found.

- Customer Quality Engineer– When a vehicle or component is produced and shipped to a customer sometimes a quality issues is identified with the product. Customer Quality Engineers interface with the end customer and help to address and resolve any quality concerns with a product.

- Purchasing Engineer– Purchasing engineers coordinate purchasing raw materials, components and sub-assemblies that are used in the production process and they balance inventories and budgets to match incoming orders and funds so that there is not an excessive amount of valuable materials being stored with no customer.

- Measurement Lab Technician– Automobiles are composed of hundreds of different components all which must come together like pieces of a puzzle. Measurement lab technicians coordinate validating the measurements of a part to ensure it meets the measurements stated on the drawing.

- Process Quality Engineer– Process Quality Engineers manage the overall quality of the production and assembly process. This important engineering role will make adjustments to the assembly and test processes to prevent defective products from being sent to the customer.

- Car Aesthetic Designer– Car Aesthetic Designers are responsible for the overall aesthetics, appearance and color selections of the car design and will work with the design engineer during the concept design phases of the vehicle.

- Acoustics Engineer– Acoustics Engineers are responsible for ensuring the vehicle design will meet noise and vibration requirements and reducing wind noise in the vehicle design to give the drivers and passengers a comfortable driving experience.

- Machining Engineer– Working as a Machining Engineer requires the engineer to machine gears, axles and other finished components that are manufactured in house.

- Norm Department/Design Engineer– When a new vehicle and all of the subassemblies are being designed the Norm Department Design Engineer will review drawings at all levels to ensure that it meets all design standards and requirements before releasing the drawings to production.

- Controls Engineer Programmer– Controls Engineers are responsible for programming essential settings in the automobile so that it will run smoothly such as shift points in transmissions or operating codes for the engine.

- Electrical Engineer Designer– Electrical Engineer Designers are responsible for all the components and internal circuitry that are included in the automobile. Electrical Engineers will design the printed circuit boards inside the subassemblies such as the instrument cluster or climate control systems.

- Safety Engineer– Safety Engineers work with the Design Engineers to incorporate safety features into the vehicle such as airbags, seatbelt pre-tensioners, and impact absorbing chassis to improve the safety rating of the vehicle.

- Sales/Application Engineer– The automotive industry is composed of highly technical products that require special skills to correctly sell by matching the correct product with the required technical specifications.

- CAD Drafter/Designer– In the old days products were hand drawn by drafters but now computer aided design (CAD) is the norm. CAD Drafter/Designers are trained in CAD software and take the requirements provided by the Design Engineers and convert them to drawings.

- Project Manager– Project Managers work across all functional areas of automotive design from concept to production. The Project Manager coordinates schedules and resources to meet the product launch timeline and customer deadlines.

- Logistics Engineer– Logistics Engineers are responsible for designing the overall flow of materials, subassemblies and components used in the production process to ensure they are efficient and arrive to the assembly line on time.

- Materials Planner– The role of the Materials Planner in automotive manufacturing is to manage the flow of raw materials, subassemblies and parts used in the production processes and balance incoming orders and material availability.

- Continuous Improvement Engineer– The Continuous Improvement Engineer will work with the existing production process and look for ways to optimize the assembly process and reduce overall cost by streamlining operations or fixing long-standing problems.

- Preventative Maintenance Engineer– Without maintenance robotics and assembly equipment will become less efficient and break down so the Preventative Maintenance Engineer develops a maintenance plan and process to keep equipment up and running.

- Sheet Metal/Body Shop Engineer– Sheet Metal Engineers are responsible working with the external body of the automobile to ensure that the large metal parts will fit together properly. The will also work with Robotics engineers on how the large parts will be assembled.

- Final Testing Engineer– The manufacturing Final Test Engineer is responsible for implement test processes in the assembly process at the end of each assembly step to ensure defective products do not get sent to the customer.

- Raw Materials Production Engineer– Raw Materials Production Engineers work with manufacturing raw materials and producing the raw parts used in machining processes.

- Industrial Engineer– Industrial Engineers are responsible for assessing the entire production process and optimizing it for cost and assembly timing so that the process is the most efficient possible.

- Quality Documentation Engineer– The Quality Documentation Engineer is responsible for maintaining all the qualification and certification required for products to be manufactured and sold.

- Materials/Metallurgical Analyst– The Materials/Metallurgical Analyst works in the quality organization and is responsible for checking material characteristics of the materials used in production to ensure they meet the material requirements.

- Root Cause Analysis Engineer– When an issues is identified during production or testing the Root Cause Analysis Engineer will lead the investigative efforts to find the root cause of the problem and put corrective measures in place so that the issue doesn’t occur again.

- Aesthetic Quality Control Engineer– Aesthetic Quality Control Engineers are responsible for ensuring that the final production vehicles meet all dimensional and visual standards before shipping to the customer.

- Quality Auditor– The Quality Auditor will conduct formal and informal audits to ensure the facility is conforming to all requirements (ISO or TS16949) and maintaining the correct documentation in day to day business.

There is such a wide variety of engineering jobs available within the automotive industry that give future engineers have tremendous amount of choices on the automotive career path that they choose. If you are looking to become an automotive engineer, there are a wide variety of ways you can do it. But no matter which field you choose there are many universities and programs available to choose from that will help you to narrow down the fields that are right for you. If you are looking for the right job for you check out our start page to help you see how to get on the right path.